90%

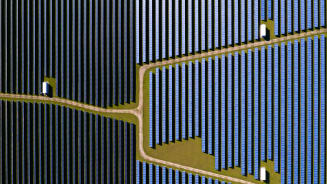

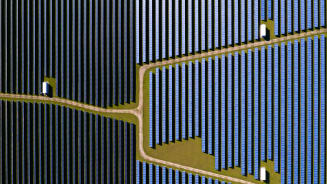

With roughly 90 percent of the world’s goods shipped by sea, the Suez Canal is one of the most crucial pinch points along global supply chains.

Before late March 2021, the Suez Canal probably wasn’t top of most people’s news agendas. That changed when the massive container ship the Ever Given ran aground in the canal March 23, blocking shipping traffic for nearly a week.

With roughly 90 percent of the world’s goods shipped by sea, the Suez Canal is one of the most crucial pinch points along global supply chains. With the Ever Given, carrying 20,000 containers and blocking the canal, thousands of ships packed with oil and goods were stuck in holding patterns in the Mediterranean and Red seas while an international rescue mission tried to refloat the ship.

With global trade already challenged by the COVID-19 pandemic, the Ever Given incident shows us again how necessary it is for organizations to understand their supply chains, find weak links and take steps to reduce the risks.

“If you look at shipping, people sit at home and click a button on their computer and get goods delivered to their house. They generally have no idea how they get there,” says Chris Bhatt, chief commercial officer, Global Marine, at Aon. “It’s only when something like this goes wrong you realize how fragile the global supply chains are. And it’s not that the vessel was too big or the quantity of vessels is too large. It’s just a fact that the supply chain is stretched, incredibly stretched.”

With roughly 90 percent of the world’s goods shipped by sea, the Suez Canal is one of the most crucial pinch points along global supply chains.

The Ever Given blockage meant that tens of thousands of containers of goods would be delayed in reaching their destinations, inconveniencing businesses and consumers waiting for those items — and affecting the companies that produced them. “A whole lot of people have probably been trying to buy appliances for their new kitchens and now they’re not going to be delivered for a while,” says Bhatt.

And, notes Richard Waterer, managing director of EMEA, Commercial Risk Solutions, at Aon, it’s not uncommon for multiple events that disrupt supply chains to occur simultaneously, much as what the world is experiencing now with the pandemic, the Suez Canal delays, the fire at a massive automobile chip manufacturer in Japan and Brexit.

“It’s quite possible that certain providers of products are going to be caught up in more than one of those events concurrently,” Waterer says. “These aren’t events that wait for each other to finish and operate in a linear way.”

And, in addition to the disruption of business operations, the impact of breakdowns in logistics systems raises another peril: reputation risk.

“Because consumers won’t separate the logistics from the provider of the product, the business involved could be hit twice: an immediate impact on revenue and profit, along with a loss of attraction in the future triggered by reputational damage,” says Waterer.

“As consumers we’ve all been lulled into believing that everything is a click away,” Bhatt says. “And that’s fine if that works, but it only works when that supply chain is absolutely fluid and nothing goes wrong.”

The Suez Canal blockage is the latest supply chain disruption but it won’t be the last. It falls on the businesses whose products, essential components or raw materials are on those ships to evaluate and address the risks.

“Whatever businesses are producing or manufacturing, they will have a portfolio of products, and some of those products will be more valuable than others, either because they generate more income or because they service a market that’s growing for them,” says Waterer. “If they can understand what’s driving the value of that business, they can then start to find the potential supply chain pinch points and risks around the end-to-end fulfilment of that product.”

Businesses should identify their “crown jewels,” Waterer says, and then determine the important suppliers and the points where a breakdown could negatively affect their ability to deliver products or services. Then they can ascertain how they might address the risk, whether it’s to hold more inventory, bring suppliers closer to home, explore new logistics options or other alternatives.

“We’re seeing companies start to think more strategically around the business continuity element,” says Waterer. “They’re asking, ‘If we do lose a portion of our stock, how can we fulfill the most important customer needs faster?’ That may mean relying on redundant supply, using a different route or another alternative.”

Our Better Being podcast series, hosted by Aon Chief Wellbeing Officer Rachel Fellowes, explores wellbeing strategies and resilience. This season we cover human sustainability, kindness in the workplace, how to measure wellbeing, managing grief and more.

Expert Views on Today's Risk Capital and Human Capital Issues

Expert Views on Today's Risk Capital and Human Capital Issues

Expert Views on Today's Risk Capital and Human Capital Issues

Better Decisions Across Interconnected Risk and People Issues.

The construction industry is under pressure from interconnected risks and notable macroeconomic developments. Learn how your organization can benefit from construction insurance and risk management.

Our Cyber Resilience collection gives you access to Aon’s latest insights on the evolving landscape of cyber threats and risk mitigation measures. Reach out to our experts to discuss how to make the right decisions to strengthen your organization’s cyber resilience.

Our Employee Wellbeing collection gives you access to the latest insights from Aon's human capital team. You can also reach out to the team at any time for assistance with your employee wellbeing needs.

Explore Aon's latest environmental social and governance (ESG) insights.

Our Global Insurance Market Insights highlight insurance market trends across pricing, capacity, underwriting, limits, deductibles and coverages.

Better Decisions Across Interconnected Risk and People Issues.

How do the top risks on business leaders’ minds differ by region and how can these risks be mitigated? Explore the regional results to learn more.

Trade, technology, weather and workforce stability are the central forces in today’s risk landscape.

These industry-specific articles explore the top risks, their underlying drivers and the actions leaders are taking to build resilience.

Our Human Capital Analytics collection gives you access to the latest insights from Aon's human capital team. Contact us to learn how Aon’s analytics capabilities helps organizations make better workforce decisions.

Read our collection of human capital articles that explore in depth hot topics for HR and risk professionals, including using data and analytics to measure total rewards programs, how HR and finance can better partner and the impact AI will have on the workforce.

Explore our hand-picked insights for human resources professionals.

Our Workforce Collection provides access to the latest insights from Aon’s Human Capital team on topics ranging from health and benefits, retirement and talent practices. You can reach out to our team at any time to learn how we can help address emerging workforce challenges.

Our Mergers and Acquisitions (M&A) collection gives you access to the latest insights from Aon's thought leaders to help dealmakers make better decisions. Explore our latest insights and reach out to the team at any time for assistance with transaction challenges and opportunities.

The challenges in adopting renewable energy are changing with technological advancements, increasing market competition and numerous financial support mechanisms. Learn how your organization can benefit from our renewables solutions.

How do businesses navigate their way through new forms of volatility and make decisions that protect and grow their organizations?

Our Parametric Insurance Collection provides ways your organization can benefit from this simple, straightforward and fast-paying risk transfer solution. Reach out to learn how we can help you make better decisions to manage your catastrophe exposures and near-term volatility.

Our Pay Transparency and Equity collection gives you access to the latest insights from Aon's human capital team on topics ranging from pay equity to diversity, equity and inclusion. Contact us to learn how we can help your organization address these issues.

Forecasters are predicting an extremely active 2024 Atlantic hurricane season. Take measures to build resilience to mitigate risk for hurricane-prone properties.

Our Technology Collection provides access to the latest insights from Aon's thought leaders on navigating the evolving risks and opportunities of technology. Reach out to the team to learn how we can help you use technology to make better decisions for the future.

Our Trade Collection gives you access to the latest insights from Aon's thought leaders on navigating the evolving risks and opportunities for international business. Reach out to our team to understand how to make better decisions around macro trends and why they matter to businesses.

Better Decisions Across Interconnected Risk and People Issues.

With a changing climate, organizations in all sectors will need to protect their people and physical assets, reduce their carbon footprint, and invest in new solutions to thrive. Our Weather Collection provides you with critical insights to be prepared.

Our Workforce Resilience collection gives you access to the latest insights from Aon's Human Capital team. You can reach out to the team at any time for questions about how we can assess gaps and help build a more resilience workforce.

Article 10 mins

Workforce-related risks — spanning health, benefits, safety systems, and data and analytics — are not just operational concerns but strategic drivers. When activated, they positively shape the total cost of risk and long-term resilience for industrials and manufacturing organizations.

Article 7 mins

As the digital economy accelerates, driven by AI and cloud computing, the U.S. power sector faces a new era of demand. Advanced gas turbines are at the heart of this transformation, but their rapid evolution brings complex risks.

Article 24 mins

Soft market conditions, ample capacity and heightened competition continued across most geographies and lines in Q4 — giving insurance buyers opportunities to secure better pricing, improve terms and expand coverage.

Article 17 mins

A dynamic and interconnected property & casualty risk landscape persists in 2026. However, the insurance market presents ample capacity and opportunities for buyers. Yet, increasing volatility means the window to build long-term resilience is time sensitive in advance of the next market turn.

Article 9 mins

On December 11, 2025, U.S. President Donald J. Trump released a new Federal Executive Order — the latest effort towards the aggressive promotion of U.S. AI leadership and away from a fragmented, state-by-state regulatory model.

Article 10 mins

By combining inclusive pension plan design with targeted engagement strategies, FAB organizations can close the retirement readiness gap and build long-term resilience for all employees.

Article 8 mins

Extreme weather poses growing risks to business operations and workforce resilience. Employers must go beyond reactive measures to protect employees and proactively plan for more frequent and widespread extreme events.

Article 13 mins

In 2026, AI-driven threats and regulatory pressures make cyber risk a board-level priority. Now is the time for leaders to act decisively — strengthening resilience and leveraging a favorable insurance market.

Article 9 mins

Organizations have access to more supply chain risk data than ever — yet few use it to its potential. Leaders who turn the wealth of available information into actionable insight set the standard for effective, data-driven supply chain risk management.

Article 6 mins

The risk management playbook is being rewritten as financial institutions navigate an era of heightened complexity and rapid change.

Article 28 mins

As workforce expectations rise and business risks intensify, HR leaders must act on five forces shaping 2026 — from AI and skills to healthcare costs, analytics, pay transparency and retirement readiness. Discover how to build a strategy that balances performance, cost and experience.

Article 10 mins

Sustainability is no longer reputational. It’s a strategic priority within risk and capital management, powered by robust data, innovation and industry expertise. For finance leaders, embedding sustainability into decision making can be critical to secure long-term value and earn stakeholder trust.

Article 12 mins

Explore second-phase GLP-1 study insights on improved medical cost growth, adherence and women’s health.

Article 15 mins

Nuclear is a critical pillar of the energy transition, addressing the dual challenges of decarbonization and surging demand. Success will hinge on managing risks across new generation technologies, regulatory shifts, financial model changes, supply chain challenges — and the acute war for talent.

Article 9 mins

In today’s volatile casualty market, businesses face mounting uncertainty from rising loss exposures and shifting risk transfer dynamics. Multi-year structured programs and other alternative risk transfer solutions can offer a smarter way to align risk duration with capital strategies.

Article 11 mins

As digital claims transformation accelerates, organizations are adopting AI, automation and analytics to improve speed, transparency and accuracy — and unlock deeper insights into risk profiles, enhancing long-term resilience.

Article 3 mins

U.S. pension risk transfer activity strengthened in late 2025, supported by competitive pricing and growing interest in buy-ins.

Article 4 mins

Litigation from workers’ compensation and liability claims is not inevitable. Discover common myths and seven practical strategies using prevention, documentation, and AI to help avoid lawsuits and protect your organization.

Article 7 mins

In a conversation with Trade Finance Global’s Deputy Editor, Mahika Ravi Shankar, Madeleine Whiteley, Senior Client Manager at Aon, explored how credit insurance is helping energy clients navigate volatility, adapt to the transition to renewables, and manage the uncertainties of today’s market.

Article 3 mins

As the U.S. renewable energy market accelerates, tax insurance is becoming critical to unlock investment, manage uncertainty, and protect returns as evolving legislation reshapes tax credits that underpin project viability.

Article 12 mins

Innovation has always driven growth in life sciences. Yet today, it’s not enough to keep organizations relevant and resilient. As global healthcare changes rapidly, the future of care depends on how well leaders align their breakthroughs with real-world healthcare delivery, affordability and trust.

Article 9 mins

While cancer care and specialty medicines are familiar culprits behind rising U.S. healthcare costs, benefit leaders should also watch out for less obvious factors driving up expenses. Taking a holistic view requires being aware of these hidden threats as you work to manage costs.

Article 8 mins

Advanced analytics empower forward-thinking risk leaders to secure better terms, anticipate volatility and build resilience. Explore three strategies to future-proof your property program through analytics.

Article 7 mins

The Trump Administration has introduced several initiatives aimed at reducing prescription drug costs. Here’s what these changes could mean for employer-sponsored plans.

Article 8 mins

The global medical trend rate is projected to dip below double digits for the first time in three years to 9.8%. It may be a hopeful sign that cost increases have plateaued, but cost increases are still elevated. We explain the risks and conditions behind the increase so employers can prepare.

Article 9 mins

Retailers in North America are navigating intense competition, shifting consumer demands and rising costs. Add to that a wave of evolving risks — from cyber to litigation — and the pressure mounts. These six insights can help retailers rethink their risk strategy.

Article 8 mins

Benefit platforms are revolutionizing the employee experience by making it easier for people to choose the right benefits at the right time. New technologies including AI, along with data insights, are enabling more personalized and relevant benefit choices.

Article 8 mins

Data center construction is booming — but cyber risk management hasn’t kept pace. As digital infrastructure becomes ever more critical, fit-for-purpose insurance solutions are essential to protect projects from costly cyber events that derail timelines and budgets.

Article 7 mins

Captives are moving from a reactive stopgap to a core, strategic tool for managing cyber risk — helping organizations drive efficiency, manage volatility and build resilience in a rapidly evolving risk environment.

Article 23 mins

Buyer-friendly conditions persisted in Q3, with ample capacity and intense competition driving continued price reductions and broader coverage for preferred risks, especially in property, cyber, and directors and officers.

Article 10 mins

Cost inflation, project complexity and tight schedules aren’t the only pressures facing infrastructure stakeholders. Emerging risks — from design and contract misalignment to tech-driven vulnerabilities — demand proactive risk management across the entire project lifecycle.

Article 9 mins

Conversations at work about mental health and finances can be daunting. That’s especially true for male employees, who fear the associated stigma. Employers can help those conversations by supporting a healthy culture and providing benefits designed to help with financial and mental wellbeing.

Article 5 mins

As H1B visa costs surge, organizations face complex decisions in talent strategy and global workforce planning. This article explores how employers, talent, and industry must adapt holistically to remain resilient and competitive amid sweeping immigration and market changes.

Article 41 mins

Explore how risk perceptions vary across countries with insights from Aon’s 2025 Global Risk Management Survey.

Article 10 mins

Latin American organizations face converging risks, but those who rethink resilience can unlock growth and gain a competitive edge.

Article 1 mins

Aon’s 2025 Global Risk Management Survey explores how organizations across four regions are responding to top risks—revealing both the challenges they face and the opportunities to build resilience in a fast-changing world.

Article 12 mins

Asia Pacific’s risk landscape is shifting fast. Organizations that rethink resilience as a strategic differentiator will be best placed to navigate volatility and seize emerging opportunities.

Article 10 mins

North American organizations face intensifying risks across cyber, supply chain, reputation, and talent. Those who rethink resilience and risk management can turn uncertainty into a source of competitive advantage.

Article 10 mins

In a region shaped by volatility and transformation, EMEA organizations are rethinking risk and resilience to unlock competitive advantage and navigate a rapidly evolving global landscape.

Article 10 mins

From drones that dodge surveillance to deepfakes that unlock doors, AI is reshaping physical security. It’s time for risk managers to rethink how they protect their organizations.

Article 7 mins

There are a few important ways AI is already influencing the health and benefit ecosystem in the U.S. Here’s how HR teams can harness their vendor ecosystem and use this technology to influence better health outcomes for their workforces.

Article 13 mins

Artificial intelligence is driving unprecedented demand for data center power, straining global grid capacity and reshaping energy strategies. Developers are racing to secure reliable energy but face complex risks and challenges.

Article 11 mins

As in-demand, high-value technology cargo travels through complex supply chains, any disruption can trigger costly delays and reputational damage. Leaders can manage volatility with a future-ready risk management approach backed by innovative insurance solutions and data-driven logistics.

Article 5 mins

Global voluntary turnover remains low, shaping cautious 2026 salary budgets and prompting a renewed focus on employee development to sustain engagement. Employers are balancing cost control with strategic investments in skills, paying high performers, pay equity and total rewards.

Article 8 mins

Financial institutions are navigating a landscape of converging risks, from cyber threats and regulatory complexity to economic volatility and geopolitical disruption.

Article 9 mins

Construction and real estate organizations are navigating a risk landscape shaped by economic volatility, digital acceleration and workforce disruption.

Article 1 mins

Business risks impact industries in different ways. Aon’s 2025 Global Risk Management Survey reveals how organizations across nine sectors are responding to today’s most pressing threats—from geopolitical volatility and cyber risk to supply chain disruption and talent shortages.

Article 10 mins

Surging input costs, supply chain fragility and geopolitical instability are reshaping the risk landscape for the food, agribusiness and beverage (FAB) industry. As organizations face mounting pressure on margins and operations, leaders are rethinking risk strategies to unlock resilience and growth.

Article 11 mins

Aon’s Global Risk Management Survey shows insurers face a convergence of risks — cyber, climate and geopolitical volatility — that demand strategic resilience, sharper underwriting and innovation to stay relevant in a shifting landscape.

Article 10 mins

Faced with fragile supply chains, regulatory upheaval and rising competition, life sciences firms are reframing risk as a strategic enabler – using analytics and alternative capital to protect innovation and unlock growth.

Article 10 mins

As geopolitical instability, workforce disruption and rapid technological change converge, the transportation and logistics industry is undergoing a strategic transformation. Organizations are rethinking supply chains, investing in automation and reshaping workforce strategies to build resilience.

Article 11 mins

From business interruption and commodity price volatility to shifting regulations and cyber threats, risks are converging to reshape the operating environment for the natural resources industry.

Article 9 mins

As disruption accelerates across the TMC industry, organizations face a complex web of risks — from cyber threats and AI upheaval to regulatory shifts and intensifying competition. Leaders are rethinking risk to build resilience, unlock growth and stay ahead in a rapidly evolving landscape.

Article 10 mins

From commodity price volatility and economic uncertainty to supply chain disruption and cyber threats, the industrials and manufacturing industry faces a convergence of risks that are reshaping the operating environment and requiring a new approach to risk.

Article 6 mins

Risk buyers can build resilience in their property portfolios by implementing a risk capital strategy that utilizes alternative risk transfer sources to access capital and support long-term program stability.

Article 10 mins

The global cyber and tech errors and omissions market continues to favor buyers — for now. As AI-driven threats, privacy litigation and supply chain exposures intensify, forward-thinking organizations are using this window to build resilience.

Article 10 mins

Succession planning is evolving. By gathering comprehensive data and adopting predictive approaches, organizations can better anticipate workforce needs and build deeper benches of future leaders.

Article 7 mins

Business interruption is the second-highest global risk in 2025 — but is expected to fall to seventh place by 2028. As interconnected threats multiply, from cyber attacks to climate events, organizations must diversify supply chains, embed geopolitical insight and regularly update continuity plans.

Article 6 mins

Cash flow and liquidity risk re-enters the top ten global risks in 2025 — and is expected to remain in tenth place by 2028. Amid an uncertain macroeconomic outlook, organizations must strengthen forecasting and unlock working capital to build financial resilience.

Article 7 mins

Commodity price risk ranks sixth globally in 2025 — and is forecast to climb to fourth place by 2028. With supply chains strained by geopolitical tensions and climate disruption, organizations should consider hedging strategies, diversifying sourcing and exploring innovative risk transfer solutions.

Article 6 mins

Cyber risk tops the global risk agenda in 2025 — and is forecast to retain the number one position through to 2028. As digital threats evolve, organizations should strengthen resilience, quantify exposure and adapt their risk strategy.

Article 5 mins

Damage to reputation or brand ranks eighth globally in 2025 — but is expected to fall to nineteenth by 2028. In an era of cyber threats, ESG scrutiny and social media amplification, organizations should quantify reputational risk and embed preventive measures into enterprise strategy.

Article 6 mins

Geopolitical volatility ranks ninth globally in 2025 — and is forecast to rise to fifth by 2028. With conflict, trade disruption and political instability on the rise, organizations must monitor global developments, regularly assess operational exposure and conduct scenario planning.

Article 5 mins

Increasing competition ranks as the fifth biggest global risk in 2025 — and is projected to climb to number three by 2028. As technological disruption, talent scarcity and geopolitical shifts intensify market pressure, organizations must embrace agility, and rethink competitive strategy.

Article 8 mins

Regulatory change ranks as the fourth biggest global risk in 2025 — and is expected to fall to sixth place by 2028. As policy shifts accelerate across sustainability, technology, trade and the workforce, organizations must adopt agile compliance strategies and unlock proactive risk management.

Article 9 mins

Supply chain failure ranks seventh globally in 2025 — and is projected to fall to twelfth place by 2028. As weather-related disruption, geopolitical tension and cyber threats converge, organizations must balance efficiency with resilience and diversify sourcing.

Article 1 mins

As risks increasingly overlap and evolve, managing them demands more than reactive strategies. This chapter explores the top-ranked risks from the survey and highlights how organizations that take a proactive, integrated approach can turn complexity into opportunity.

Article 6 mins

Economic slowdown ranks as the number three global risk in 2025 — and is projected to rise to number two by 2028. Amid trade tensions, inflation and geopolitical instability, organizations must strengthen liquidity, enhance workforce agility and rethink capital strategies to stay resilient.

Article 11 mins

Spanish energy multinational, Iberdrola – a leader in grids, storage and clean energy – talks with Aon about its efforts to adapt and respond to climate impacts through its shift towards renewables and building a workforce for the future.

Article 6 mins

Total rewards professionals must adapt quickly to changes in the workforce. Whether it's personalization of benefits powered by AI or a whole new language around total rewards, the near future may look very different than the status quo.

Article 10 mins

As pay transparency regulations increase, companies must update their pay-for-performance strategies and ensure performance management and compensation are clear, fair and well-documented.

Article 17 mins

Data and analytics can unlock value for HR professionals in a variety of ways. From a unified global benefits perspective to personalizing total rewards, gathering and analyzing the right types of data help companies optimize what can be their biggest expense.

Article 12 mins

Aon’s 2025 U.S. Health Survey shows how leading employers are responding to rising people risks by evolving their benefit strategies to address affordability gaps, legal pressures and rising employee expectations.

Article 8 mins

SPACs are staging a comeback, but the risks that surrounded them in prior cycles remain. The challenge is to lead with proactive, strategic risk transfer that keeps stakeholders and balance sheets protected in a fast-evolving landscape.

Article 13 mins

Efficiency, safety and innovation are no longer enough in aviation. Leaders must now take decisive action to manage emerging risks and future-proof operations in a sector under intense scrutiny.

Article 10 mins

The transportation industry is one of the highest emitters of greenhouse gases — and among the most primed for change — but the journey to decarbonize remains complex. Stakeholder collaboration will be critical in making sustainable fuel mainstream in aviation and marine.

Article 8 mins

How pay and benefits are managed in M&A transactions creates a lasting impression on employees. Mismanagement can lead to disengagement and attrition, eroding deal value. But the challenge of integrating employee benefits can also bring opportunities to improve business outcomes.

Article 5 mins

In a rapidly evolving tax environment, tax insurance is more than a safeguard — it’s strategic risk capital that unlocks value and accelerates deal confidence.

Article 5 mins

Despite unprecedented investment in digital transformation across Asia Pacific, there is a disconnect between cyber risk and capital allocation. Organizations are racing to innovate, yet the adoption of cyber risk capital trails behind the velocity of cyber threats.

Article 8 mins

For public companies and their executives, facing a Securities Class Action (SCA) can be an overwhelming and unprecedented time. While the stakes are high, the procedural roadmap of an SCA typically follows a consistent trajectory.

Article 12 mins

Strategic acquisitions and divestitures are essential for survival and growth in the FAB industry, but increasing risks demand a reevaluation of traditional dealmaking tactics.

Article 12 mins

Relevance is not a phase — it’s a discipline. In a market defined by volatility, insurers must embed strategic relevance into every decision to outperform through the cycle.

Article 9 mins

Climate change is now a central disruptor for FAB industries worldwide, impacting every tier, from raw production to global supply chains. Extreme weather, shifting rainfall patterns and regulatory changes are altering the landscape for every organization within the value chain.

Article 6 mins

Patient access to critical life sciences products is at risk when supply chains are disrupted. In a dynamic risk landscape, organizations are leveraging stock throughput insurance along with advanced risk strategies to ensure continuity, compliance and reputation.

Article 5 mins

Organizations must prioritize addressing critical cyber security vulnerabilities to comply with the EU’s NIS2 Directive and help bolster their resilience against cyber threats.

Article 7 mins

Pay transparency is more than another regulatory mandate. It’s a foundational shift in how leading organizations are building resilient cultures and future-ready workforces — especially as scrutiny extends beyond base pay.

Article 22 mins

Dynamic trends are influencing the size and complexity of claims around the world. Proactive claims management can help organizations recover swiftly after a loss event and manage potential claims exposures.

Article 6 mins

While the global property insurance market currently favors buyers, it is uncertain how long this will last. Businesses should act now by adopting a proactive, data-driven property risk strategy that aligns financial stability and risk appetite with market dynamics.

Article 7 mins

Non-profit organizations in the U.S., Canada and the UK in particular, face unprecedented regulatory scrutiny and financial instability. Here are ways to strengthen investment strategies at a critical time using an OCIO model.

Article 10 mins

Avoid limiting a portfolio’s capacity based on the capabilities or bandwidth of an existing process by working with the right partner.

Article 10 mins

The rapid growth of renewables demands innovative risk solutions. Captive insurance offers a strategic, flexible approach to managing evolving risks — helping energy leaders navigate volatility, optimize capital and unlock new opportunities in the transition to sustainable power.

Article 8 mins

The energy landscape is rapidly changing, presenting the re/insurance industry a unique opportunity to facilitate the transition to a sustainable economic model.

Article 11 mins

Against a backdrop of unsettled global markets, financial institutions can still capitalize on M&A opportunities by refining strategies and retaining focus on long-term ambitions.

Article 9 mins

Mass timber construction is gaining traction for its sustainability and efficiency, yet it brings distinct insurance and risk management challenges that require industry collaboration and proactive strategies.

Article 12 mins

As business demands grow more complex, employers must offer a total rewards package that balances the varied needs of the workforce with financial sustainability. Explore ways to ensure an effective total rewards program with data and timely communications.

Article 6 mins

Forecasters predict another above-average North Atlantic hurricane season. Businesses should use their saved premium dollars to strengthen their hurricane-prone properties and workforce, and treat risk management as a strategic asset.

Article 9 mins

The global marine cargo market faces many risks, ranging from shipping delays to geopolitical tensions. These challenges can be mitigated through a risk capital approach, which uses strategic capital allocation and data-driven insights.

Article 8 mins

Ensuring the safe delivery of construction materials along shifting trade channels is no simple endeavor. Learn how specialized insurance and risk management can support the transportation of construction cargo and help ensure project success.

Article 9 mins

Industry shifts and innovations are creating both new opportunities and challenges for life sciences organizations. Optimizing risk capital can enable business leaders to uncover cost efficiencies, strengthen resilience and enhance control.

Article 13 mins

The FAB industry faces significant supply chain challenges requiring innovative solutions and strategic planning. As organizations work to optimize capital and manage costs, they must also address geopolitical risks and regulatory updates.

Article 11 mins

With rapid technological advancements, directors and officers face increasing liabilities. Proactive risk management and board oversight can ensure organizational resilience.

Article 10 mins

In today's uncertain economic climate, finance leaders must innovate beyond traditional financial metrics, managing risk capital through targeted risk strategies, holistic capital approaches and proactive stances toward emerging threats.

Article 6 mins

With looming deadlines on pay transparency regulations, establishing an effective job architecture is foundational to compliance and preparation. We explore how a data-led approach can speed the process while maintaining objectivity.

Report 13 mins

Global business leaders highlight risks linked to trade as some of their top concerns — both physical and financial. While the topic is complex and broad, there are opportunities that business leaders can pursue to stay ahead of emerging trade dynamics.

Article 5 mins

As property underwriters become increasingly concerned and cautious with catastrophe-prone risks, buyers are turning to alternative property solutions, including parametric, to fill protection gaps in their programs.

Article 6 mins

Half of the world’s top economic loss events impacted the U.S. in 2024. As natural catastrophes continue to grow in frequency and severity, enhancing a business continuity strategy helps ensure organizations are prepared for the unexpected.

Article 12 mins

While medical and pharmacy expenses continue to consume benefit budgets, employers can adopt effective cost-saving strategies that combine predictive analytics with innovative solutions to help control healthcare spend over a multi-year period.

Article 8 mins

Employers are increasingly looking to defend the health and safety of their employees in a changing climate. By modeling the impact of weather on employees like they do for physical risks, employers can proactively establish solutions to protect workers.

Article 7 mins

A variety of growing risks, including shareholder derivative actions, an evolving regulatory environment and bankruptcy filings, are why public and private organizations must protect their corporate directors and officers.

Article 15 mins

Organizations in EMEA face unprecedented challenges as cyber threats become more sophisticated. In the face of emerging AI, evolving regulations and geopolitical tensions, businesses should strengthen their resilience to better navigate the complexities of the digital age.

Article 6 mins

In a volatile climate, institutional investors are turning to outsourced chief investment officers to conquer administrative, regulatory and market challenges.

Article 6 mins

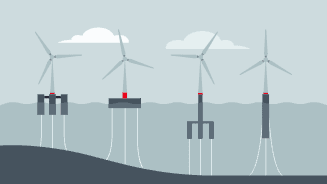

Investment in both onshore and offshore wind power is key to not only energy security, but also wider social and economic benefits through the creation of jobs and investments in local communities around the world.

Article 8 mins

In today's intricate business environment, growth is expanding to include more than financial success. By understanding how to fund, shape and secure growth, organizations can build resilience and drive long-term value.

Article 6 mins

AI in the renewable energy sector is revolutionizing how we produce, manage and consume energy. As AI continues to evolve, industry leaders must find innovative ways to harness its full potential.

Article 8 mins

Despite higher claims frequency, the cyber and tech E&O markets remain in a favorable pricing and well-capitalized environment. However, buyers must remain vigilant and manage a variety of current and emerging cyber risks and threat actor attack methods.

Article 4 mins

Organizations can demonstrate their commitment to global sustainability and a low-carbon future by addressing verification challenges and adopting best practices.

Article 15 mins

Market stability prevails in management liability lines as insurers continue to seek market share. However, expanding technologies, increased litigation and macroeconomic factors are causing growing uncertainty and underwriting concerns.

Article 7 mins

There is an opportunity to develop a strategy around financial education in the workplace. Globally, our latest data finds 11 percent of employees receive financial education from their employer, but 37 percent expect it. How can employers bridge this gap?

Article 12 mins

With growing global regulations and rising stakeholder and talent expectations, pay equity has shifted from a mere HR initiative to a top C-suite priority that goes beyond compliance.

Article 7 mins

A well-structured open enrollment process is one that leverages innovative technology, encourages cost-effective use of healthcare resources and reduces unnecessary spending — benefiting both employees and employers.

Article 3 mins

Aon’s Risk Analyzer Suite delivers quantitative analytics, improved risk insights and supports operational efficiency.

Article 15 mins

After a period of significant volatility, a more optimistic outlook is on the horizon for the life sciences industry in 2025. With the right level of preparedness, firms can take full advantage of the potential opportunities the new year will bring.

Article 6 mins

Decarbonizing construction demands new materials and approaches, with a focus on managing risk and securing capital. By aligning sustainability with business strategy and risk management, the industry can meet net-zero targets.

Article 8 mins

Nearly 20 million people get cancer each year,<sup>1</sup> and the impact is far-reaching — from those diagnosed to their loved ones and colleagues. When developing a meaningful cancer prevention strategy, employers must show empathy and compassion while managing rising costs.

Alert 14 mins

In the face of the L.A. wildfires, impacted businesses’ top priority is their people. A three-phased approach can help build business resilience and mitigate the effects of future events.

Article 23 mins

Rapid growth in data center construction, spurred by AI advancements and cloud demand, creates interconnected risks for developers. However, with effective risk management solutions, navigating this dynamic market while prioritizing sustainability is possible.

Article 8 mins

In an industry with tight operating margins, FAB organizations face significant challenges in managing spend and protecting their financial health — requiring industry leaders to adopt a sophisticated approach to risk capital optimization.

Article 15 mins

The risk capital landscape is poised for change, driven by emerging trends reshaping market dynamics. With a buyer-friendly market currently prevailing across most lines, opportunities abound for strategic investment and risk management.

Article 9 mins

When a workers compensation claim goes to litigation, expenses rise dramatically — a burden that is often shouldered by the business. To mitigate attorney-related costs, organizations should re-think their approach to engaging injured workers and use artificial intelligence to enhance outcomes.

Article 35 mins

Human resources is increasingly involved in all areas of a company’s strategy. As the workforce changes, HR leaders should identify and leverage these five important and evolving trends.

Article 6 mins

Long-term care is expensive, and costs are rising due to shortages. With the population aging at the fastest rate in a century, finding solutions to pay for care is an urgent priority. How can employers support this growing population?

Article 7 mins

With a multi-generational and diverse workforce, it is important for employers to develop benefit communications and engagement strategies to help employees understand their unique benefit options. Here are five useful tips to consider.

Article 13 mins

Rising medical costs are a global phenomenon. Aon’s 2025 Global Medical Trend Rate Survey found that costs are projected to rise 10 percent in 2025.

Article 7 mins

As healthcare costs continue to rise, employers are trying to balance the need to take care of their workers with the need to keep costs under control. Aon’s 2025 U.S. Health Survey provides insights into the choices employers are making, and their potential effects on costs.

Article 9 mins

Pension reforms in Europe are reshaping retirement planning, demanding more oversight from employers and new strategies for employees’ financial wellbeing.

Article 6 mins

Non-financial risks are often difficult to predict and quantify, yet present a real threat to financial institutions. In this volatile environment, risk management is playing a greater role in creating business resilience and identifying where capital should be deployed.

Article 9 mins

Daniel Halter, Director Global Insurance at Sandoz, discusses how smart risk and insurance management supported the Sandoz core mission to provide affordable, off-patent medicines to patients who need them most with Ana Serdarevic, Head of Aon’s Transaction Advisory Services for DACH.

Article 7 mins

Business leaders are aware of AI-driven cyber risks and their implications. But understanding changing risk profiles to make better decisions around the management of new exposures is the key to cyber resilience.

Article 8 mins

U.S. freight and commuter rail industries are facing excess liability and property issues for different reasons. These railroads are critical to infrastructure and vital to the economy, yet finding effective solutions remains complex.

Article 11 mins

As private companies prepare for an IPO, they face increased risks that require directors and key leaders to adopt essential risk management strategies to ensure a smooth transition.

Article 10 mins

As climate change intensifies the frequency and severity of extreme weather events, public entities and businesses need more flexible funding solutions. Parametric stands out as an adaptable resource capable of swiftly responding to potential disasters.

Article 17 mins

Funding challenges due to macroeconomic factors have prevented several green and blue hydrogen projects from getting off the ground. Organizations facing hurdles in accessing capital can work with risk and insurance experts to expedite projects and help make the promise of hydrogen a reality.

Article 11 mins

Learn how strong human capital strategies can help recruit, retain and motivate vital talent in a competitive and evolving job market.

Article 7 mins

As corporate boards meet to discuss strategy, including any changes to executive compensation, there are key trends to consider for the year ahead.

Article 6 mins

Companies aiming to be a net-zero company may face many challenges during the biofuels transition. Read more on risk strategies to cut through complexity.

Article 6 mins

With DC schemes growing across Europe, many organizations are realizing the importance of ensuring strong performance from their investments. Here’s how asset owners and managers can optimize DC outcomes through the right investment strategy.

Article 9 mins

With no federal paid leave law in the U.S., employers have limited guidance in designing equitable and comprehensive paid leave programs to support their workforce. Looking beyond compliance to focus on strategy and values will help create fair and well-designed policies.

Article 8 mins

Amid economic uncertainty, companies are taking a careful approach to hiring and salary planning — one that includes focused hiring strategies, revising salary budgets and implementing measures that respond to the current economic environment.

Article 8 mins

Hurricanes Helene and Milton insured loss estimates are expected to fall between $34 billion and $54 billion. Healthy, well-capitalized insurance and reinsurance markets are positioned to absorb those losses.

Article 17 mins

Buyer-friendly conditions continued across much of the global insurance market in Q3, painting a largely positive picture as we head into year-end renewals.

Article 10 mins

A successful M&A strategy relies on due diligence across financial, legal, human capital, technology, cyber security and intellectual property risks. As cyber threats become more complex, robust cyber due diligence in private equity and acquisitions is increasingly necessary.

Article 8 mins

Cargo theft in the transportation industry is escalating, driven by sophisticated criminal tactics that exploit both physical and digital vulnerabilities. Businesses must adopt proactive risk management strategies to counter these evolving threats.

Article 11 mins

Trade, technology, weather and the workforce are interconnected trends shaping the future of business in North America. Understanding them is key to long-term resilience.

Article 9 mins

Competition and capacity are dominating the cyber liability market and pricing remains favorable as a result. Taking advantage of the current buyer’s market to build sustained cyber resilience is the key to success.

Article 10 mins

The growing renewable energy sector is boosting M&A activity. Risk transfer solutions can help unlock capital access in these transactions.

Article 7 mins

Digitalization presents both opportunities and challenges in life sciences, driving new organizational approaches to human capital to keep up with evolving talent needs while building a resilient workforce.

Article 5 mins

As financial institutions reshape human capital strategies for the digital age, leaders face pressure to balance the risks and opportunities of digitalization.

Article 9 mins

Employers are concerned that previous wellbeing strategies aren’t moving the needle enough. But when wellbeing is part of an organization’s culture, it has positive effects on costs, engagement and productivity.

Article 6 mins

Financial institutions can increase their resilience to volatile threats through enhanced risk management frameworks and innovative models powered by people data and technology.

Article 10 mins

As the deadline for implementing the EU Pay Transparency Directive fast approaches, some financial institutions feel unprepared to comply. These five steps can help guide the way through the upcoming regulatory landscape.

Article 9 mins

Thriving organizations rely on thriving employees to succeed. With healthcare costs on the rise, it’s time for employers to challenge the status quo in providing health benefits. Organizations need to consider the human side of these increases and take bold action to achieve better outcomes.

Article 9 mins

The aviation industry is watching the rise in nuclear verdicts with concern as social inflation and associated risks continue to squeeze the sector. Organizations should review their risk management processes to limit the dollar value of future losses.

Article 12 mins

As AI evolves, directors and officers must maneuver through a complex landscape of regulatory and legal risks. Implementing best practices around the use of AI and robust governance-focused risk mitigation can help manage exposures.

Article 11 mins

Middle market organizations face unique challenges in the ever-changing cyber environment, requiring holistic insurance solutions and enhanced resilience readiness to manage risks that could impact profitability.

Article 17 mins

With life expectancies and retirement ages on the rise, organizations can capitalize on the value that older employees offer and support them by fostering a workplace where both the business and its people thrive.

Article 8 mins

As climate change compounds wildfire risk, organizations play a critical role in protecting their workforce before and after an event.

Article 10 mins

The transportation and logistics industry faces unique challenges which can negatively impact employees' health. A cultural shift to more tailored wellbeing strategies can improve health outcomes and boost company performance.

Article 6 mins

Pooled employer plans (PEPs) can offer a streamlined solution to the retirement planning challenges inherent in spin-off and M&A events.

Article 20 mins

The role of HR professionals is becoming more strategic, which requires collaboration with other areas of an organization to help drive growth. Given that people and benefit costs are a large portion of business expenses, partnering with finance is a natural step forward.

Article 5 mins

Aon analyzes employee perception about return to office policies following the COVID-19 pandemic, as well as recent actions one organization took for alleged lack of remote employee productivity.

Article 11 mins

Despite subdued global M&A in 2023, positive trends have been emerging in the M&A insurance market to help clients improve their deal-making and ‘value-protection on investment’.

Article 7 mins

Graeme Hudson and Ghonche Alavi from Crisis24 discuss Crisis24’s approach to Political Evacuation and Threat Management with Cara LaTorre from the Financial Services Group at Aon.

Article 8 mins

European construction contractors are looking with increasing interest at Asia, but to expand successfully into the region, they need to overcome key workforce and market challenges.

Article 8 mins

As digitalization presents new risks and opportunities for life sciences organizations, implementing cyber and data resilience ensures that innovation doesn’t result in business interruption.

Article 7 mins

For insurers, making decisions on where and how to deploy capital becomes more difficult during times of volatility.

Article 5 mins

Employers in the U.S. should understand the unique risks associated with voluntary benefit captives when considering alternative insurance arrangements for their voluntary benefit plans.

Article 7 mins

Workers compensation is an area of risk management that could benefit from a more holistic approach. A safety program that incorporates wellbeing and uses data in a meaningful way can contribute greatly to lowering costs.

Article 8 mins

Firefighters face a unique set of risks and long-term health consequences from their jobs. Aon worked with Minnesota firefighters to create a benefit program to address three primary health issues.

Article 8 mins

Open legacy workers compensation claims place rising financial burdens on employers, who are faced with closing out aged claim inventory and improving their balance sheets in the process.

Article 5 mins

Organizations must consider the impact of climate change on property, which will vary now and years into the future. Therefore, a thoughtful approach can enhance risk mitigation and resilience strategies.

Article 8 mins

Helping midsize organizations strike the right balance between risk and compliance with a comprehensive regulatory and compliance framework.

Article 5 mins

As U.S. employers balance costs with providing employees more value from their benefits, creating an annual healthcare enrollment process that includes more choice and guidance can accomplish both goals.

Article 10 mins

With many insurers reporting healthy profits in 2023, and in response to notable improvements in the reinsurance market, the insurance market in Q2 2024 remained growth-oriented.

Alert 3 mins

On July 19, 2024, the CrowdStrike outage became one of the largest IT events in history, impacting businesses and customers around the world. Leaders now have an opportunity to reexamine technology dependencies and business continuity plans to mitigate similar risks in future.

Article 6 mins

Insurers are some of the world’s largest institutional investors. Recognising their crucial role in driving the global climate transition, they should identify and analyse climate-related risks and opportunities to improve long-term risk-adjusted returns.

Article 7 mins

The global CrowdStrike IT outage demonstrated that even non-malicious cyber incidents may have serious repercussions. Events like these serve as a wake-up call for businesses to review their cyber resilience and be prepared for more significant incidents in the future.

Article 4 mins

More global benefits professionals are aligning benefit strategy to an employer’s identity and values.

Alert 10 mins

CrowdStrike, a global cybersecurity firm, released an update for its Falcon sensor, which caused system crashes on Microsoft Windows systems globally.

Article 8 mins

Cyber incidents continue to grow in frequency and severity, especially as new technology emerges. While D&O and cyber liability policies offer distinct coverage differences, terms need to be carefully structured to avoid potential gaps.

Article 6 mins

Insurers are venturing into the thriving digital landscape of the Metaverse, covering virtual assets, safeguarding intellectual property, and protecting the wellbeing of users and avatars. With this evolution, comes new challenges and the unique opportunity to shape the future of insurance.

Article 10 mins

Record-warm Atlantic Ocean temperatures and a shift to La Niña conditions have led forecasters to predict an extremely active Atlantic hurricane season in 2024. Learn how to build business resilience to mitigate risk for hurricane-prone properties.

Alert 7 mins

The U.S. Supreme Court has changed the way laws are interpreted in the development of regulations. This change has the potential for far-reaching consequences for both regulatory agencies and employers.

Article 4 mins

Overview of the current trade credit insurance market and outlook on trend developments.

Article 11 mins

The need to attract and retain high-quality talent in an environment of intense competition is at the forefront of professional services leaders’ minds.

Article 11 mins

Renewable energy is critical to meet net-zero targets, but as the industry grows, so do cyber attack surfaces. Learn how to prepare for emerging threats and support long-term ambitions.

Article 7 mins

As the scale and speed of interconnected risks escalate, innovative risk management strategies help FAB businesses build the resilience and agility needed to thrive.

Article 10 mins

The renewable energy sector is undergoing a sweeping transformation, as it plays a pivotal role in the challenge to achieve global net-zero goals. Attracting, upskilling and retaining talent is critical for sustainability.

Article 7 mins

Contractors in EMEA face an array of risks they must mitigate or transfer while managing the complexities inherent in major construction projects.

Article 12 mins

As more companies seek to reduce their carbon footprint, the renewable energy sector continues to grow, presenting both opportunities and red flags for organizations with renewable energy growth plans.

Article 6 mins

Proactive risk management and data-driven reshoring strategies can empower risk managers in logistics companies to navigate supply chain complexities with confidence.

Article 5 mins

As more companies become comfortable using captives and understanding the value they add, captives are likely to become further embedded into corporate risk strategies, regardless of market conditions.

Article 6 mins

Helping midsize organizations leverage key partnerships to address challenges around talent, market, regulatory compliance, and leveraging capital.

Article 12 mins

A rapid rise in medical plan costs is being driven in part by high-cost claimants — a high-risk group that disproportionately accounts for a large amount of healthcare costs. Here are strategies for addressing this issue.

Article 9 mins

Online benefits platforms are a key component of the overall employee value proposition. As employers maximize the ROI of their people spend, here are four tips which may assist with implementing a successful online benefits platform.

Article 8 mins

Efforts to bring more transparency to pay practices shine a light on benefits equity — and it’s not only about wages and salary.

Article 3 mins

The rapid pace of digitalisation means that organisations in the UK are constantly struggling with the ever-present threat of cyber attacks.

Article 2 mins

Equity has an important part to play in a balanced strategy to improve the attraction and retention of key employees.

Article 2 mins

How are business leaders adapting to a generational change in how work gets done?

Article 2 mins

Lori Goltermann, CEO of Regions and Enterprise Clients, Aon examines the main issues discussed at the event.

Article 2 mins

Our panel discussion looked at the issues facing corporate treasurers and how they have become more complex and interconnected.

Article 3 mins

Businesses are still in search of competition, alternatives and innovation in their insurance programmes.

Article 2 mins

Companies and financial sponsors are constantly seeking innovative and capital-efficient ways to facilitate M&A deals.

Article 2 mins

Professor Trevor Williams analyses the latest indicators and what they mean for the UK — and global — economy.

Article 2 mins

How Aon is moving further, faster to bring new, innovative solutions that address companies’ risk and people challenges.

Article 5 mins

Today's employers need to continually learn and adapt to emerging technologies and skills if they are to thrive in the talent landscape.

Article 6 mins

Collective retirement plans are growing in popularity and improving employees’ financial wellbeing in the process. Other advantages that haven’t been as widely explored include how these retirement structures allow HR to shift its focus to strategy.

Article 8 mins

Getting ahead of risk is vital for North American construction contractors, as they aim to manage evolving issues, while delivering job safety, solving workforce shortages and containing project costs.

Alert 6 mins

The Department of Labor released a final rule increasing overtime protections for the standard salary level threshold for the “white collar" exemptions and the threshold for employees classified as Highly Compensated Employees. Employers need to prepare for these significant changes.

Article 10 mins

Climate change adaptation and the transition to net zero present huge premium growth opportunities for insurers. The key question is how to get started.

Article 7 mins

As the cyber insurance landscape continues to evolve in EMEA, companies need actionable insights and solutions to strengthen their cyber risk strategies.

Article 9 mins

The challenges of 2023 eroded the buffers that many insurers had previously enjoyed, bringing an increased focus on capital management and a variety of capital sources according to Aon’s capital poll.

Article 6 mins

As healthcare costs rise, voluntary benefits are a critical component of engaging employees, while also helping to manage direct and indirect medical expenses. Here are three strategies for employers to make the most of their voluntary benefits.

Article 8 mins

The expansive scope, stringent sanctions and pivotal role of management related to the new NIS2 Directive provide a strong foundation to protect against evolving cyber risks.

Article 8 mins

The London insurance market seeks a generation of game-changers who can navigate uncertainties and drive innovation to ensure the industry’s future success in a digitalised world.

Article 15 mins

Artificial intelligence is having a measurable impact across all aspects of HR — from talent management to compensation, health and benefits, and retirement planning. To effectively harness the technology, HR leaders must ensure both their own teams and the wider workforce are prepared.

Article 8 mins

Advanced analytics can empower organizations with deeper insights into the risks and opportunities surrounding renewables, while also supporting energy transition investment.

Article 17 mins

Positive performance in 2023 fueled insurer growth ambitions but underwriting remained disciplined in the first quarter of 2024.

Article 12 mins

While digitalization is delivering transformational change to R&D across the sector, it is also rapidly reshaping recruitment and retention strategies.

Alert 6 mins

The FTC has announced a rule that bans noncompetes and clauses that have a similar effect. While the rule will face legal challenges, employers should take steps now to prepare for an environment where they cannot use noncompete agreements.

Article 7 mins

Risk advisory services can help construction stakeholders navigate uncertainties, optimize performance and drive growth in their projects.

Article 9 mins

While there are similarities in the risk profile of floating offshore wind and bottom-fixed offshore wind, challenges like unproven technology and tow-to-port strategies for maintenance require a collaborative approach between owners/developers and their insurance partners.

Article 4 mins

Macrotrends are transforming our world and creating emerging property-casualty exposures, which will have profound implications for the insurance industry.

Article 7 mins

Understanding market trends and future projections in an evolving cyber insurance market is paramount to strengthening risk mitigation and transfer strategies.

Article 5 mins

In an era of escalating climate-related challenges, the construction industry is turning to advanced climate modeling to fortify its risk management strategies.

Article 14 mins

Advances in technology will not only transform healthcare and treatment outcomes — benefit offerings, access to care, diagnosis, treatment and affordability challenges will also be radically changed. Here is what to expect as these efforts take shape globally.

Article 10 mins

As healthcare costs continue to rise, employers are struggling to balance cost control with attracting and retaining talent. The results of Aon's 2024 U.S. Health Survey point to key strategies organizations are using to help.

Article 11 mins

As the world races to reduce climate risks and limit CO<sub>2</sub> emissions, the demand for scalable and cost-effective decarbonization technologies is increasing. Carbon capture projects form an important part of the low carbon energy transition, bringing both challenges and opportunities.

Article 7 mins

Growing extreme heat conditions have escalated risks, delays and costs for the construction industry in North America. Parametric insurance can help protect against such risks, offering contractors and building owners agility, efficiency and flexibility.

Article 9 mins

The launch of the Unified Patent Court allows for a new patent filing process across Europe using a centralized system. While this brings significant financial and operational benefits, navigating these changes will demand a robust litigation risk management strategy.

Article 8 mins

Construction projects in EMEA are often impacted by extreme heat, leading to project delays and increased costs. Many heat exposures are excluded by traditional markets, however, parametric is a flexible solution that can help mitigate these risks.

Article 12 mins

New regulations in the U.S. and Europe will require companies to be more transparent about their pay practices. Combined with willingness among workers to talk about salary, the era of pay transparency is here.

Article 11 mins

As companies tailor their health and benefits to meet the needs of their employees, vital areas for support include family building and menopause.

Article 7 mins

Complex market dynamics in the construction industry are pushing organizations to proactively explore alternative risk transfer solutions, including parametric insurance and captives.

Article 11 mins

As new job roles and technologies emerge in the natural resources industry, employee expectations are also shifting. Leaders must rise to the challenge of securing talent to meet the world’s future energy needs.

Article 5 mins

Rulemaking from the Securities and Exchange Commission (SEC) highlights the importance of company transparency with investors and regulators around risk management and the impact of cyber events.

Article 13 mins

Five ways financial institutions can balance investment with prudence in an uncertain economic climate.

Article 12 mins

An increasingly interconnected and complex risk landscape continues to shape risk strategies and market responses.

Article 13 mins

To be successful, business leaders must keep pace with the key trends that will impact the risk and insurance landscape in 2024.

Article 9 mins

Taking a new approach to talent management and planning for worker shortages can help businesses in the energy and power industries build greater operational resilience.

Article 11 mins

For investors, climate change means navigating uncertainties and understanding a wide range of potential outcomes.

Article 8 mins

Extreme cold and freeze were responsible for $15 billion worth of structural damage in recent years, as well as business interruption and supply chain impacts. We explore the threat chronic hazards pose and consider the influence of climate change on business.

Article 7 mins

The global D&O market remains soft, creating a favorable environment for buyers. With abundant capacity and increased competition, capitalizing on conditions now is critical as rates are showing signs of moderating.

Article 15 mins

It's never been more important for HR leaders to help shape and support the execution of business strategies. However, to be successful in today’s volatile world, HR teams must stand ready to understand and harness five fast moving trends.

Article 9 mins

Supply chain disruptions can have serious reputational repercussions, causing plummeting shareholder value and diminished stakeholder trust. The potential fallout underscores the need for management strategies that collectively address these risks.

Article 13 mins

To feed a growing global population, FAB organizations must build operational resilience to overcome supply chain, cyber, geopolitical and climate risks.

Article 7 mins

Businesses considering pension risk transfer to mitigate volatility should prepare now to be well-positioned for market opportunities.

Article 7 mins

Improving retirement plan governance is crucial during economic uncertainty. Collective retirement plans, like a pooled employer plan, reduce risk and streamline administrative expenses for employers while also boosting employee support.

Article 4 mins

Senior executives aren’t letting a tough market for transactions stop them from finding new approaches to closing deals.

Article 6 mins

Organizations faced complex challenges in risk capital and human capital throughout 2023, prompting leaders to turn to new ways of doing business.

Article 8 mins

Good agricultural practices reduce emissions, expand carbon sequestration and benefit the supply chain from the very first mile — all key components of achieving future climate goals.

Article 3 mins

Hear from Aon and industry thought leaders to increase your working knowledge of Parametric Solutions through our four-part educational video series.

Article 7 mins

By taking a 360<sup>o </sup>view of employee wellbeing, leaders can build the resilience of their organizations while improving workplace experiences.

Article 6 mins

Parametric solutions have the flexibility to make hard-to-predict and often uninsurable “grey swan” events insurable. Such is the case for earthquakes — a potentially catastrophic risk across the globe.

Article 9 mins

The insurance industry can help the economy transition to alternative energy sources and mitigate the impacts of climate change — from facilitating capital for clean technologies to protecting people and businesses.

Article 7 mins

Technological innovations offer business leaders many opportunities to improve the cost and efficacy of employee health and benefits plans.

Article 6 mins

The non-standardized nature of cyber and E&O policy wording creates the opportunity to mold an individually tailored and responsive risk transfer tool.

Article 8 mins

With medical costs on the rise, companies are looking for ways to avoid passing the increased financial burden onto employees.

Article 5 mins

As data becomes more advanced and precise, so does parametric insurance as a risk solution — a win-win for both risk managers and insurers.

Article 7 mins

The landscape for U.S. and UK pension plans has changed greatly. Companies are mitigating risks to meet regulatory requirements and protect their employees and finances.

Article 6 mins

As hiring and employee turnover slows down, employers have an opportunity to rethink their salary increase strategy for 2024.

Article 7 mins

With more brands looking to reposition themselves in the fashion and luxury industry and secure their future, a robust workforce resilience strategy will be key.

Article 7 mins

In a landscape where IP is increasingly becoming integral to company valuations, many business leaders, boards, patent attorneys and litigation teams are making IP insurance a key asset in their toolkits.

Article 12 mins

Medical costs continue to rise around the world. Aon’s Global Medical Trend Rate report provides insight into what conditions are driving these increases.

Article 7 mins

Insurance CEOs are well aware of the talent crisis: they’re fully engaged and seeking answers.

Article 11 mins

Gene and cell therapies represent breakthrough advances in medicine, but they also have significant costs and potential risks for patients, employers, insurers, governments and manufacturers.

Article 11 mins

In the wake of record-breaking high global temperatures in 2023, the rising frequency of extreme heat due to climate change creates an urgency for the risk industry to analyze climate trends for better risk mitigation.

Article 12 mins

(Re)insurers must embrace AI technology to successfully navigate today’s emerging transformative trends that are shaping the insurance landscape.

Article 4 mins

Technology, media and communications businesses need to understand how climate change threatens their operational resilience. Parametric insurance is becoming an important part of the solution.

Article 8 mins

Creating the right mix of talent will be key for capturing (re)insurance growth opportunities as transformative trends shape the future landscape.

Article 11 mins

With medical costs continuing to rise globally, Aon’s 2024 Global Medical Trend Rates Report examines the risk factors driving the increased costs.

Article 6 mins

New pay transparency laws are forcing employers to develop a pay disclosure strategy and make decisions like whether to voluntarily disclose salaries where it’s not legally required.

Article 9 mins

The strategic use of credit solutions (credit insurance, political risk insurance and surety) can enhance liquidity, improve transaction returns, facilitate capital-efficient deal closures, and support long-term value creation.

Article 11 mins

The SEC published nine new Compliance and Disclosure Interpretations (C&DIs) covering the pay versus performance rule. The C&DIs focus on when awards are considered vested and the valuation of equity awards in specific circumstances.

Article 9 mins

As the need for climate-resilient infrastructure grows, the industry contends with changes in regulations, building strategies and risk.

Article 9 mins

Burnout and languishing threaten individual and organizational productivity and business outcomes. A company’s employee wellbeing strategy can help prevent them by mitigating microstress.

Article 4 mins

A holistic understanding of climate risks requires a multidimensional approach to data, risk models and developing staff expertise.

Article 8 mins

With a robust exit strategy, financial sponsors can create value from day one and enable a strong long-term outlook.

Article 9 mins

Addressing the retirement pay gap issue between men and women starts with first acknowledging it exists. Then companies can conduct further analysis and adjust their benefit plans accordingly.

Article 5 mins

Secondary deal activity will likely continue to strengthen as financial sponsors navigate widespread macroeconomic uncertainty.

Article 7 mins

Organizations can refresh their employee pension communications with these five tips to help people connect with their retirement planning.

Article 6 mins

Pricing pitfalls are more common than you think, whether it's working with incomplete data or key man risk – but with the right pricing process, many of these issues can be mitigated. Read our article to learn about the most common pricing errors, and what insurers can do about it.

Article 5 mins

In today's increasingly complex insurance landscape, an inadequate pricing system can not only impact insurers' view of risk, but also prevent them from making the right decisions at the right time. Read our article on why it's essential to get pricing right.

Article 7 mins

By leveraging the advances made by academic research, companies can develop more robust climate risk resilience.

Article 6 mins

Climate modeling has been around for decades but mainly used by academic and government scientists. Led by the risk industry, the private sector is adapting these models to broadly assess the physical impacts of climate change.

Article 9 mins

With the continued threat of rising temperatures, companies should focus on building climate and weather-related impacts into their overall workforce resilience plans.

Article 9 mins

Companies recognize that wellbeing is more important than ever. But the programs they offer don’t always match what their employees need.

Article 4 mins

SECURE 2.0 is changing retirement planning for businesses and employees. Strategic decisions will be critical in building sustainable retirement plans.

Article 6 mins